NOTE! This site uses cookies and similar technologies.

If you not change browser settings, you agree to it. Learn more

Prodotti

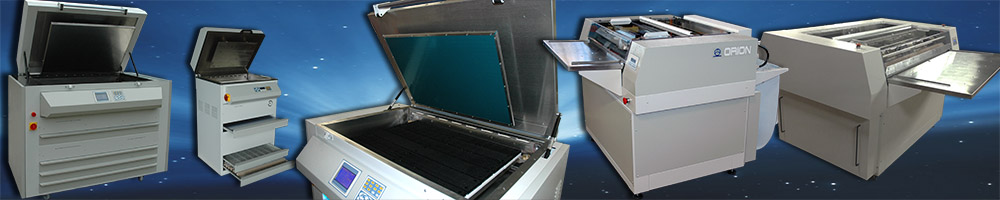

FLEXO Photopolymerf processing Machines mod. ETRA

Model ETRA to treat flexo photopolymers, both water-based and solvent-based All models

perform the following functions:

EXPOSURE: in a drawer with pneumatic table, dry suction pump and special UVA lamps.

DEVELOPMENT: in a tank made completely in stainless steel with height adjustable brushes for the various thicknesses of photopolymers to be treated.

DRYING: in two drawers with thermal ventilator controlling the temperature by thermostat.

All functions of the machine are controlled by a 10 programmable channels computer.

Starting from size 35 x 50 cm, the machines can be fitted with a further additional drawer for post-exposure made by special UVC germicidal lamps and also equipped with two pumps for extracting vapours and fumes produced during development, drying and post-exposure.

Etra machines conceived to treat solvent based polymers are prepared to be connected to SOLV-ER unit (art. F0287 - optional), allowing the filling, draining, replenishment and circulation of the solvent in the washing tank

ETRA when conceived to treat water-based flexo polymers, are already prepared to be connected to WATER-FLEX filtering unit (ART. F0286) allowing circulation of the washing solution through three filters. WATER-FLEX filtering unit, together with the optional atomizer unit, keep

both the brushes and the washing tank totally clean and free from any trace of polymer waste.

Etra can also be equipped with permanent adhesive green carpet in the washout unit, which ensures a perfect adhesion of the plate on the orbiting support , avoiding the use of doublesided tape. For a perfect definition of the point Etra is the only one who can mount a device

to control the speed and acceleration of the orbital plate support in the washing unit. It can also be provided with a kit spray water and air for a perfect cure of the plate before placing in the drying section, and a lighting on exposure area to precisely control the vacuum in dark environments.

Tutti i marchi sono registrati e dei legittimi proprietari

©2024 OMM - Officine Meccaniche Marchetti | Joomla Templates Modify by Tecnosoft Informatica